Installation - Plafonds BZ systems Inc

Main menu:

Installation

Technology of installation

Steps of installation of ceiling

Step 1 - Set a special profile around the perimeter of the space where the stretch ceiling will be installed

Step 2 - Prepare the film;

Step 3 - The film is mounted diagonally over the room;

Step 4 - The film is mounted to the every corner of the profile prepared by the first stage;

Step 5 - The film is fixed around the perimeter. After the lights are embedded your ceiling is ready!

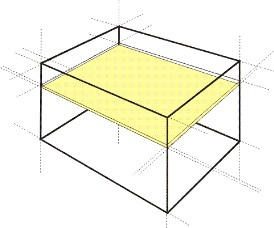

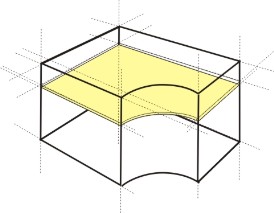

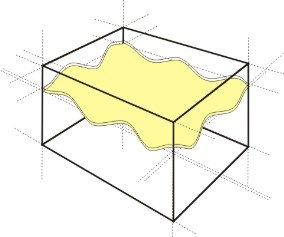

Stretch ceiling technology allows one to achieve any form of ceilings within a two-dimensional plane (straight lines, acute and obtuse angles, arcs, waves, circles). It is possible to articulate a transition between two planes situated at different heights. This can be done using a straight line as a step or smoothly in the form of a wave. Tilting the planes at any angle or in any direction can be easily achieved.

Refined stretch ceiling technology as well as a large variety of components allow the creation of three-dimensional ceilings in any shape-and-form, from a simple rectangular shapes to sophisticated organic configurations. It is even possible to design dynamically changing structures. There is no limit to the forms you can create!

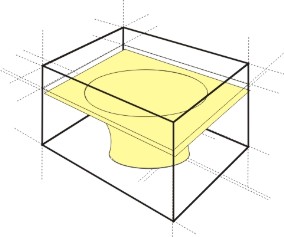

Stretch ceiling technology allows one to link multiple plains (the ceiling and the floor, for example) using a volumetric ceiling. This connection may materialize as a column, partition, three-dimensional flower, etc. Resilient and flexible stretch ceiling membrane, a variety of rails and sub-framing give your imagination a great freedom.

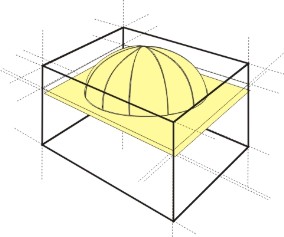

We have identified this form of ceiling as a separate group because there are some particularities in creating spherical and cylindrical elements.

It takes several petal-shaped pieces of membrane put together to create a spherical form. Therefore, the greater the frequency of petals, the closer the form is to the ideal sphere. However, increasing the number of petals increases the cost. Therefore, the designer must find a compromise between the ideal form and the price.

Also, considering the physics of tension materials, it is impossible to create a perfect cylinder. The resulting form will have a small deflection in section.